Also known as setting oil, dielectric lubricant is a highly effective synthetic silicone-based lubricant that offers many benefits. Not only does it repel water and safeguard against corrosion of electronic components, but it also acts as a thermal insulator. In the case of automotive glow plugs, the use of insulating oil can greatly improve their function and prolong their service life. By creating a protective barrier, it prevents moisture from entering, reduces the risk of arcing, and ensures stable spark plug performance. This comprehensive article will guide you through the correct placement of spark plug dielectric grease, offering you step-by-step guidance and practical tips for proper maintenance. With this valuable information at your fingertips, you can maximize the efficiency and reliability of the car’s ignition engine.

What is Dielectric Grease?

Silicone grease, otherwise referred to as silicone-based compound, is a specialized substance that serves as a self-sealing, non-conductive sealant for mechanical interconnects. Its main purpose is to create a protective barrier that seals out moisture and prevents corrosion, ensuring the longevity and reliability of your vehicle’s electrical systems.

With its high-heat resistance and excellent insulating properties, dielectric grease acts as a safeguard against electrical faults and more damages caused by moisture and contaminants. By inhibiting corrosion and protecting connections, it helps maintain the original functionalities of electrical contacts, connectors, and switchgear.

By incorporating dielectric grease into your maintenance routine, you can be confident that your electrical connectors are well-protected and that your vehicle’s electrical systems will continue to operate reliably, even in challenging conditions.[1]

Where to Apply Dielectric Grease on Spark Plug

When it comes to application of spark plug lubricant, proper placement is essential to ensure optimum operation and to avoid causing any possible candle damage. Apply the lubricant gently to the inner surface of the glow rod, which is the component linking the plug to the coil. Use a small quantity of lubricant to prevent excessive accumulation.

It is worth noting though that dietary lubricant must never be applied directly to the electrodes of the plug as it can result in ignition problems. By following these guidelines and taking the time to ensure proper application of the lubricant, you will be able to keep those plugs properly maintained and your engine running at peak efficiency. [1]

Directions for putting dielectric grease onto a glow plug

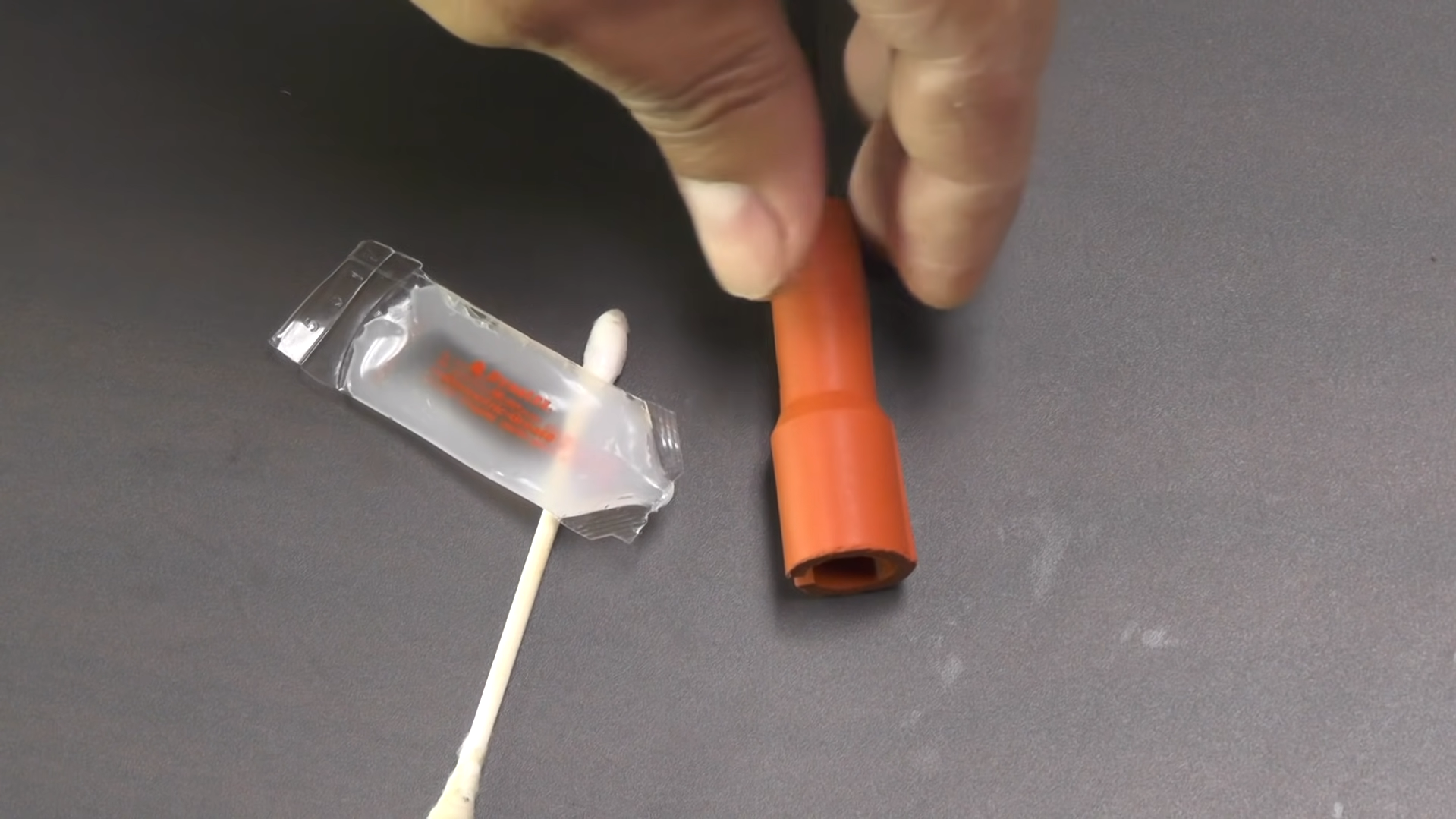

Follow these steps below to coat the platinum spark plugs with dielectric grease to help ensure proper operation and service life:

- Gather together the required tools: a tube containing grease and a clean cloth or towel.

- Begin by turning off your vehicle and allowing the engine to cool if it was recently running. This step tends to be critical in order to ensure security and avoid accidental burns.

- Once the engine has cooled, locate the spark plugs in your engine bay. Typically, they are situated along the top or side of the engine. Take a moment to familiarize yourself with their position.

- Carefully detach the candle shoe with the pulling it back from the spark plug itself. This may require a gentle twist or wiggle to break the seal. Be cautious not to damage the trunk or ignition plug.

- Use a clean rag to remove any dirt or rust residue from the interior of the socket. Ensuring a clean surface will allow for better adhesion of the dielectric grease.

- Now, here comes the main action. Dispense a tiny bit of insulating lubricant, about the size of a snap pea, on a finger or small brush. This amount is usually sufficient to cover every single spark plug.

- Smear the inside of the spark plug socket with grease, ensuring it coats the inside evenly. Pay attention to any areas that may have been previously exposed to moisture or corrosion.

- It’s crucial not to over-apply the grease, as excess grease can lead to a weak spark or misfire. A thin, even layer is all that’s necessary for effective protection.

- Once the grease is applied, carefully reconnect the spark plug boot to the spark plug. Make sure it is properly seated and secured to avoid any potential issues.

- Repeat this process for each spark plug in your vehicle, taking your time to ensure thorough and consistent application.

By following these detailed steps and applying dielectric grease in this manner, you create a protective barrier that helps prevent moisture intrusion and corrosion. This safeguard ensures the optimal performance and longevity of your spark plugs, keeping your vehicle running smoothly. [1]

What Are the Different Between Dielectric and Lubricating Grease

Dielectric grease and lubricating grease are both incredibly versatile tools that find application in a wide range of mechanical and electrical settings. Despite their shared versatility, these greases serve distinct purposes and offer unique benefits.

Let’s start with dielectric grease. As mentioned earlier, it is a silicone-based grease that boasts non-conductive properties. Its primary function is to safeguard electrical connectors from the detrimental effects of moisture and corrosion. By forming a protective barrier, dielectric grease ensures the preservation of the original functionalities of electrical systems, such as spark plugs. It effectively repels moisture, shielding the connectors and preventing any potential damage that could arise from exposure to water or other corrosive substances.

In summary, both dielectric and lubricating grease offer exceptional protective benefits. However, they are tailored for distinct applications. Dielectric grease excels in preserving and insulating electrical connections, while lubricating grease excels in reducing friction and promoting smooth movement in mechanical parts. [2]

Advantages

Utilizing dielectric grease on spark plugs comes with multiple advantages that can significantly enhance the overall performance and lifespan of your vehicle’s ignition system. Firstly, by providing an excellent seal against moisture intrusion, the grease effectively protects the spark plug connections from corrosive elements that can degrade their performance over time. This is particularly beneficial in regions with high humidity or frequent rainfall, where moisture-related corrosion is a common issue that can affect the reliability of the ignition system.

Secondly, the application of dielectric grease helps maintain the integrity of the spark plug boot. The grease acts as a protective barrier, reducing the boot’s exposure to high temperatures and preventing it from sticking to the spark plug. This not only contributes to prolonging the boot’s lifespan but also ensures consistent performance by preventing any interference caused by a compromised boot.

In summary, the use of dielectric grease on spark plugs serves as a simple yet highly effective preventative measure to safeguard your vehicle’s ignition system. By ensuring optimal performance and longevity, it provides peace of mind and allows you to enjoy a smooth and reliable driving experience for years to come. [2]

Disadvantages

While dielectric grease provides many advantages, it isn’t without its disadvantages. Firstly, misuse or improper application of dielectric grease can lead to suboptimal performance or even damage to your vehicle’s ignition system. It’s crucial to apply the grease correctly, avoiding direct contact with the spark plug’s electrode or connector, as this can cause a weak spark, misfire, or hinder the flow of electricity, ultimately affecting the engine’s performance.

Secondly, over time, dielectric grease has the potential to attract dust and dirt. Although it’s not conductive, the accumulation of debris could gradually lead to a short circuit if not regularly cleaned. This necessitates additional maintenance to ensure the continued effectiveness of your spark plugs and prevent any potential issues.

Lastly, it’s important to consider the cost implication of using dielectric grease. While it’s not overly expensive, it does add to the overall expenses of vehicle maintenance. If you’re operating on a tight budget, this could be a noteworthy consideration when deciding whether to use dielectric grease on your spark plugs.

Despite these potential drawbacks, when applied properly and with proper maintenance, the benefits of using dielectric grease on spark plugs generally outweigh the disadvantages. It’s crucial to ensure the correct application and ongoing care to fully enjoy the protective and longevity-enhancing benefits of dielectric grease for your vehicle’s ignition system. [2]

Where Can You Apply Dielectric Grease Besides the Spark Plug

Dielectric grease is a versatile compound with a multitude of applications, extending beyond just spark plugs, thanks to its exceptional protective and insulating properties. One notable use is its application on battery terminals, where it acts as a barrier against corrosion, ensuring a secure and reliable connection. This not only promotes battery longevity but also contributes to consistent vehicle performance, especially in demanding conditions.

Moreover, dielectric grease finds utility in various other electrical connections within your vehicle. It can be applied to bulb sockets and electrical plugs that are often exposed to the elements, offering invaluable moisture and corrosion resistance. By safeguarding these vulnerable areas, dielectric grease helps maintain optimal electrical conductivity and prevents potential failures.

However, it is important to note that dielectric grease should not be used in situations where electrical conductivity is required, as it is a non-conductive compound. Its purpose lies in protecting and insulating electrical connections rather than facilitating them. If you have any doubts about the appropriate use and application of dielectric grease, it is always advisable to consult a professional to ensure optimal results. [3]

FAQ

Where do you apply dielectric grease to a spark plug?

When using dielectric grease on a spark plug, it’s crucial to apply it correctly to avoid issues. Apply the grease to the inside of the spark plug boot, not directly onto the spark plug itself. Remove the boot and apply a thin layer of grease to its inner surface. Then, reattach the boot to create a seal that keeps out moisture and prevents electrical leakage. Avoid applying grease to the metal tip or electrode area to ensure optimal ignition system performance.

Should I put dielectric grease on my spark plugs?

Applying dielectric grease on spark plugs benefits the ignition system. Correct application is crucial to prevent issues. Place the grease inside the spark plug boot, covering the surface that touches the ceramic part. This creates a seal against moisture and electrical leakage, enhancing performance and lifespan. Avoid applying grease to the metal tip or electrode area, as it can block the connection, leading to suboptimal performance or damage. Follow instructions carefully and consult a professional if unsure. Despite the need for caution, using dielectric grease on spark plugs is recommended for vehicle upkeep.

How do you apply dielectric grease to a spark plug boot?

To improve your vehicle’s ignition system, follow these steps for applying dielectric grease to a spark plug boot:

- Gently remove the spark plug boot using the correct tools to avoid damage.

- Thoroughly clean the inside of the boot to remove dirt and old grease.

- Apply a thin layer of dielectric grease to the entire inner surface of the boot that contacts the ceramic part of the spark plug.

- Reattach the boot to the spark plug to create a moisture-sealing seal and prevent electrical leakage.

Remember not to apply dielectric grease to the metal tip or electrode area of the spark plug, as this can disrupt the electrical connection. Always refer to the manufacturer’s instructions or consult a professional if needed.

Do NGK plugs need dielectric grease?

NGK plugs, like other spark plugs, can benefit from using dielectric grease. While not strictly necessary, it can enhance performance and longevity. Dielectric grease creates a moisture-proof seal, preventing corrosion and ensuring a solid connection between the spark plug boot and ceramic plug.

However, it’s crucial to apply the grease correctly. Only apply it to the inside of the spark plug boot, avoiding the metal tip and electrode area. Applying grease there can interfere with the electrical connection and affect ignition system performance.

Despite their high quality, NGK spark plugs are not immune to moisture and electrical leakage. Using dielectric grease with NGK spark plugs, when applied correctly, can help maintain the ignition system. When in doubt, consult a professional or follow the manufacturer’s instructions.

Where should you not use dielectric grease?

Dielectric grease is important for maintaining your vehicle’s ignition system, but its usage requires caution. While it’s beneficial for the spark plug boot, it can have negative effects if applied to the metal tip and electrode area. These areas must maintain a strong electrical connection for proper spark plug function, and applying grease here can interfere, leading to suboptimal performance or damage. Additionally, avoid using dielectric grease as a general lubricant. Its purpose is insulation and moisture protection, not facilitating movement or reducing friction between parts. Don’t use it on moving parts or areas prone to high heat. Lastly, be mindful not to apply it to areas that require electrical conductivity. Always use dielectric grease carefully and consult a professional if needed.

Can too much dielectric grease cause misfire?

Using excessive dielectric grease can potentially cause misfires in your vehicle’s engine. Dielectric grease is primarily used to insulate and protect spark plug connections from moisture and corrosion, not to facilitate electrical conductivity. Applying too much grease can interfere with the necessary electrical connection between the spark plug and ignition system.

If dielectric grease is applied too liberally and makes contact with the metal conductor of the spark plug, it can inhibit the electrical spark, leading to a misfire. To prevent this, apply dielectric grease only to the inside of the spark plug boot, avoiding the metal tip or electrode area.

Remember, less is more when using dielectric grease. A thin layer is sufficient for moisture protection and a secure connection. Always follow the manufacturer’s instructions and consult a professional if unsure.

Where do you apply dielectric grease?

Apply dielectric grease to the inside of the spark plug boot, the part that makes direct contact with the spark plug’s ceramic portion. To do this, carefully remove the boot, clean it thoroughly, and then apply a thin layer of grease to the inner surface that contacts the ceramic part. Reattach the boot, and the grease will act as a seal against moisture and electrical leakage.

Note: Do not apply dielectric grease directly onto the spark plug itself, especially not on the metal tip or electrode area. This non-conductive grease can interfere with the necessary electrical connection, causing ignition system malfunctions.

Should I put dielectric grease on all electrical connections?

Dielectric grease is not suitable for all electrical connections. It is a non-conductive compound, which means it does not allow electric current to flow. Applying it directly to electrical connections can block the flow of electricity and hinder their function. Dielectric grease primarily insulates and protects against moisture and corrosion, rather than facilitating electrical connectivity. Therefore, it is best used on non-metal parts of electrical connections, like inside spark plug boots, to create a moisture-sealing seal and prevent electrical leakage. Always refer to the manufacturer’s instructions or seek professional advice for safe and effective application of dielectric grease.

Useful Video: How To Properly Use Dielectric Grease On Spark Plug Wires

Conclusion

The correct use of dielectric grease is crucial in maintaining and enhancing your vehicle’s ignition system performance. Remember, it is intended for the interior of the spark plug boot to protect against moisture and prevent electrical leakage. It should never be applied to the spark plug’s metal tip or electrode area as it is a non-conductive compound and can inhibit the necessary electrical connection, thus causing your ignition system to malfunction. Furthermore, it’s not a universal lubricant for all types of electrical connections. Always use it sparingly and with caution, adhering strictly to the manufacturer’s instructions or seeking professional advice if in doubt. By doing so, you can ensure the longevity of your spark plugs and the overall health of your vehicle’s ignition system.

References:

- https://theautovibes.com/where-to-apply-dielectric-grease-on-spark-plug/

- https://getjerry.com/car-repair/dielectric-grease-on-spark-plugs

- https://www.thedrive.com/maintenance-repair/39173/dielectric-grease

Leave a Review